SPECIAL CLEANING FOR THE MILK PROCESSING INDUSTRY

Prevention, reduction and cleaning

Controlling the microbiology of milk and dairy products begins with the producer and continues to be an essential factor during transport and throughout the various stages of manufacturing the finished products. Hygiene is a matter of priority for producers in the dairy industry and demands continuous vigilance. Continual self-monitoring is fundamental to minimise and prevent contamination risks from pathogens such as salmonella, listeria and Escherichia coli, as well as chemical residues from pesticides, biocides and technical additives.

The objective is to ensure that the food is always safe for the customer’s health and enjoyment. In addition, hygiene and safety in the workplace must also be brought into balance with environmental issues. Planet Innovation GmbH is dedicated to holistic concepts that focus on saving energy, time, raw materials and resources as well as protecting employees. Our competent specialist staff and the wide range of products offered by Planet Innovation GmbH allow us to identify various forms of contamination and remove them safely, even in complex systems such as microfiltration plants, as well as to establish microbial safety.

AREAS OF APPLICATION:

- FILTRATION

UF, MF, NF, RO, ROP - CLEANING IN PLACE (CIP) SOLUTIONS

- BELT LUBRICATION

- TANK CLEANING

- WATER TREATMENT

Waste water, vapours, cooling water

- WATER TREATMENT

Additional disinfection - EVAPORATOR

OBJECTIVE

Significant time and cost savings due to less effort and personnel

Reduction of energy costs

Complete and holistic disinfection

Reduction of the cleaning time

Less risk and more product and yield security

Removal of biofilms and organic contaminants without mechanical intervention

Reduced contact / handling of disinfectants

Water savings and Predictable disinfection and cleaning costs

Improvement of the water quality

Reduction of undesirable bacteria, fungi, spores and viruses

Enabling error-free / error-reduced production

Removal of biofilms and protein adhesions with the products from Planet Innovation GmbH

The formation of biofilms takes place in several stages. It is not only dependent on the type of microorganisms and their properties, but is also influenced by the surface properties of the materials that are being populated as well as the environmental conditions. Their removal is often very difficult and time-consuming. We use a cleaning procedure developed by ourselves to remove biofilms.

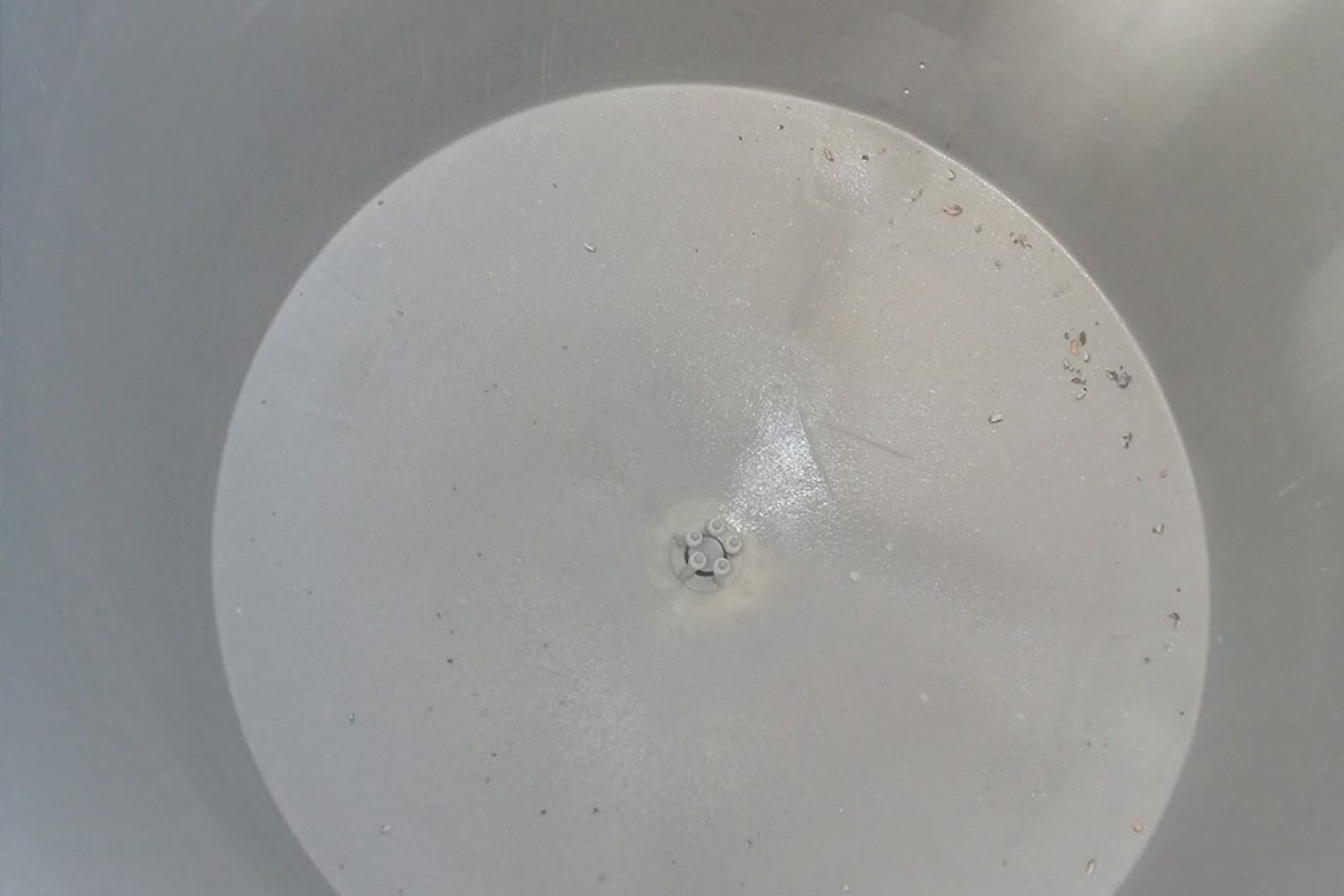

The figures illustrate biofilms and protein adhesions in large-scale food production facilities. As seen in the direct comparison between the figures, the combination of our cleaning and disinfection concepts enables a residue-free and microbially safe removal of biofilms.