SPECIAL CLEANING IN BEVERAGE PRODUCTION

Prevention, reduction and cleaning

It is essential to protect food and beverages from germs, mould and pathogens at all times. Beverages have a particularly vulnerable position in this respect due to their high water content and percentage of sweeteners.

A comprehensive and holistic hygienic approach to the production and processing of all raw materials prevents illnesses as well as losses for customers and producers.

We ensure professional hygiene solutions for your company.

AREAS OF APPLICATION:

- TANKS AND PIPELINES

- CONTAINERS, BARRELS, ETC.

- BELT CLEANING

- BELT LUBRICATION

- FERMENTATION CELLAR

- BREWHOUSE

- SURFACE CLEANING AND DISINFECTION

- MEMBRANE SYSTEMS

- FILLING SYSTEMS

- WATER TREATMENT

- PERSONNEL HYGIENE

OBJECTIVE

Significant time and cost savings due to less effort and personnel

Reduction of energy costs

Complete and holistic disinfection

Reduction of the cleaning time

Less risk and more product and yield security

Removal of biofilms and organic contaminants without mechanical intervention

Reduced contact / handling of disinfectants

Water savings and Predictable disinfection and cleaning costs

Improvement of the water quality

Reduction of undesirable bacteria, fungi, spores and viruses

Water savings and Predictable disinfection and cleaning costs

Enabling error-free / error-reduced production

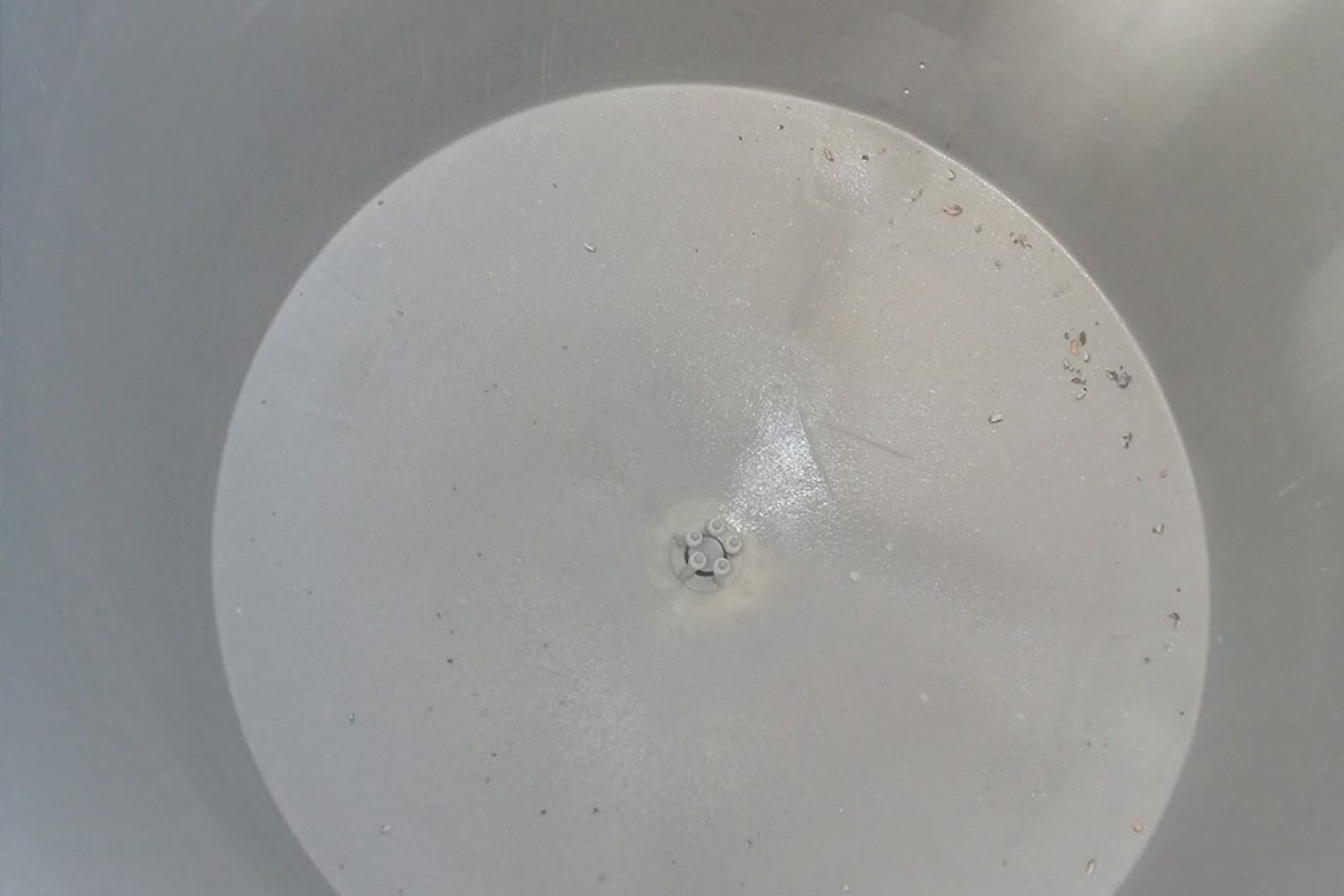

Removal of biofilms and protein adhesions with the products from Planet Innovation GmbH

The formation of biofilms takes place in several stages. It is not only dependent on the type of microorganisms and their properties, but is also influenced by the surface properties of the materials that are being populated as well as the environmental conditions. Their removal is often very difficult and time-consuming. We use a cleaning procedure developed by ourselves to remove biofilms.

The figures illustrate biofilms and protein adhesions in large-scale food production facilities. As seen in the direct comparison between the figures, the combination of our cleaning and disinfection concepts enables a residue-free and microbially safe removal of biofilms.